PSA Technology

PSA Technology

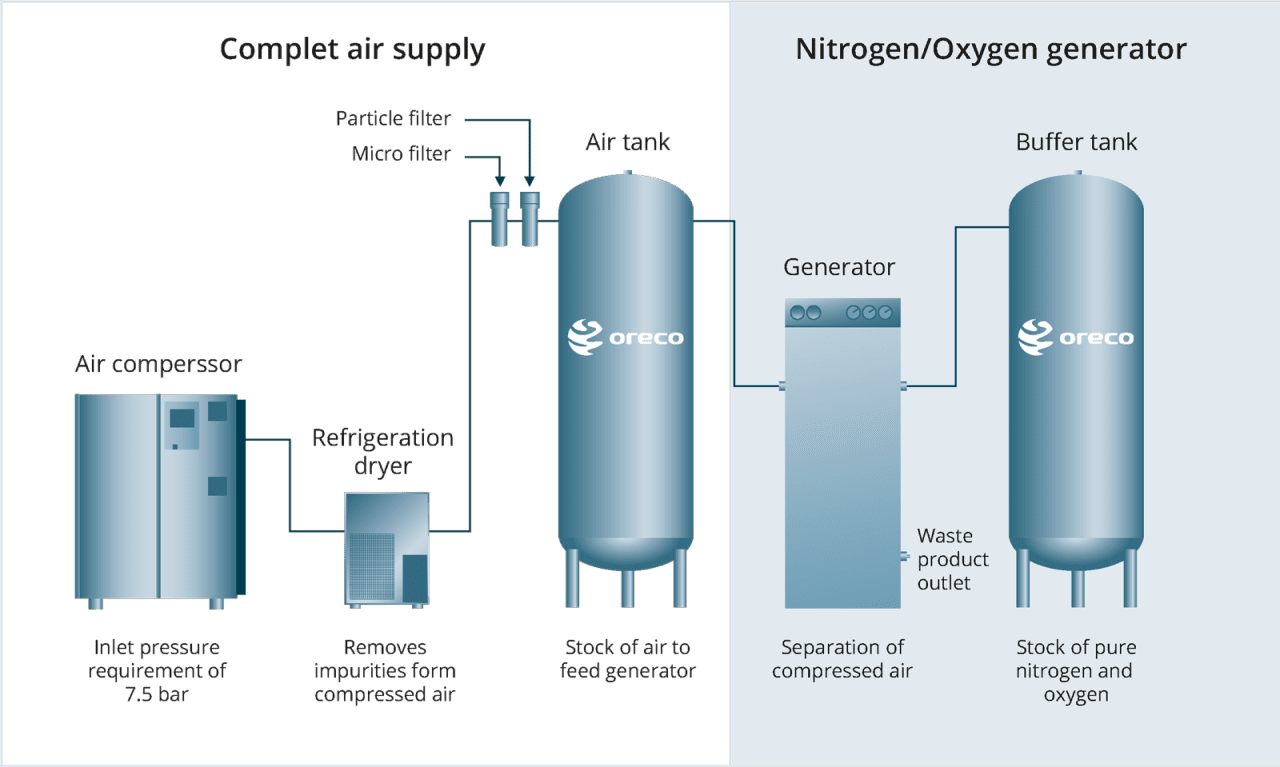

All Oreco PSA nitrogen and oxygen generators are based on the Pressure Swing Adsorption (PSA) technology, which we have chosen over other technologies due to its advantages in terms of reliability, system lifetime, purity, and cost-effectiveness.

To learn more about the process. Please see below

Why PSA?

Higher Efficiency: PSA systems use less compressed air than membrane solutions—saving energy while delivering the same nitrogen output.

Higher Purity: Achieve nitrogen purity up to 99.999%—without compromising on energy efficiency

Flexible & Scalable: Easily adjust nitrogen purity and expand capacity as your needs grow—one system that adapts to your operations

Low Operating Costs: With no moving parts in the PSA itself and minimal wear on process valves, maintenance is low—and so are your operating expenses.

Long-Lasting & Robust: CMS in PSA systems lasts longer than membranes and handles impurities in inlet air far better—reducing replacement costs and downtime

Smart Control & Monitoring: PSA systems offer advanced control and real- time monitoring—ensuring reliable performance and full process transparency

Designed Differently.

Built with Purpose

Made in Denmark – From Start to Finish

Agile and Customer-Focused

Customer-Focused

General Installation

Installation, Commissioning & Training – Support When You Need It

Our systems are designed for easy self-installation, supported by clear, step-by-step manuals that guide you through the process. Prefer hands-on help?

Our experienced team is ready to assist—either on-site or remotely. We also offer commissioning support to ensure your system runs perfectly from day one. For added confidence, we provide

thorough training—either during Factory Acceptance Testing at our facility or on-site during commissioning—so your team feels fully prepared to operate the system with ease.